Quick understanding of the cosmetic packaging bronzing process

Jul 26, 2023|

Jul 26, 2023| View:387

View:3871. Process definition

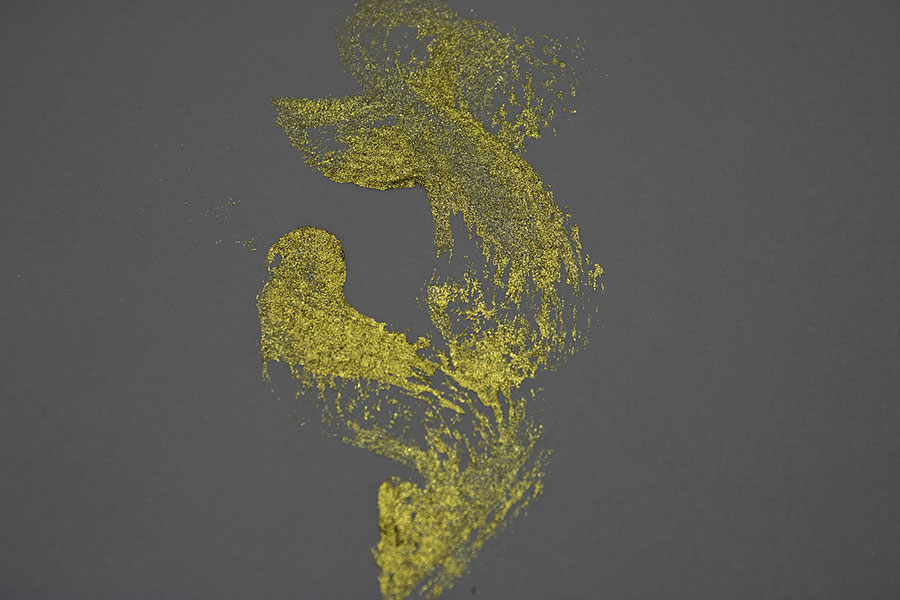

Stamping refers to the use of a certain pressure and temperature, installed in the hot stamping machine on the template, so that the printing and hot stamping plate in a short period of time pressure, the processing technology of transferring metal foil or color pigment foil to the surface of the hot-stamping material according to the picture and text requirements of the stamping template. As a result of hot stamping is mainly gold and silver, so often called stamping.

2. Process characteristics

Process cost: mold cost (very low), unit cost (low)

Typical products: surface treatment of consumer electronics, packaging, stationery, and printed matter

Suitable output: small batch or large batch

Quality: bronzing details of high quality

Speed: fast production cycle, about 1000 units per hour

3. System composition

3.1 Bronzing machine

There are many types of stamping machines, semi-automatic, and automatic stamping machine, brand is also diverse.

3.2 hot stamping plate

Hot stamping version of the general copperplate, zinc version, and resin version, relatively speaking, the best copperplate, zinc version moderate, resin version slightly worse. Therefore, for fine hot stamping, should be as far as possible with copperplate. For a short-run plate, the requirements of its surface level, graphics, and text lines are clear, smooth edges, no pitting, and burrs. If the surface is slightly uneven or slightly abraded, fuzzing, fine charcoal can be used to gently wipe, so that it is smooth. In order to ensure the clarity of the picture and text, to reduce the appearance of join and paste, and to improve the rate of resistance to printing, the depth of the decaying plate should be slightly deep, at least 0.6 mm and above, and the gradient should be about 70 °. Hot stamping of the text, lines, and patterns of design is very fastidious. The picture and text should be as thick and thin as possible moderate, dense reasonable, such as too small too thin, easy to break off the stroke; too thick too dense, it is easy to paste version.

3. 3 Gilding paper (also known as gold foil)

The utility model is made by taking a polyester film as a chip-based Kodak, coating an alcohol-soluble dyeing resin layer, vacuum spraying a metal aluminum, and then coating an adhesive layer. It consists of base film layer, an alcohol-soluble dyeing resin layer (which can be divided into an isolation layer, dyeing layer), an aluminum layer, and an adhesive layer

4. Process Flow

The process of stamping includes hot stamping preparation → plate mounting → pad → determination of hot stamping process parameters → hot stamping → signature → formal hot stamping.

The technology is mainly based on the principle of hot-press transfer. The hot stamping plate has a certain amount of heat due to the heating of the electric heating plate. The heating of the electric heating plate makes the hot-melt layer of dyeing resin and adhesive melt, the viscosity of the dyeing resin layer decreases, while the viscosity of the special heat-sensitive adhesive increases after melting. The aluminum layer is peeled off from the anodized aluminum base film and transferred to the substrate for high-fidelity printing, adhesive rapidly cooling solidification, aluminum layer is firmly attached to the substrate to complete a hot stamping process.

5. The use of cosmetic packaging materials

The bronzing process in cosmetic packaging applications is very wide because it does not use ink, is environmentally protected, is clean, and is suitable for plastic, glass, paper, and other materials, the bronzing process in plastic bottles, glass bottles, paper boxes, and other cosmetic packaging surface have applications

View More(Total0)Comment lists