Design Principle

It is applied to Thin creams, Serums, Facial Mask Creams, Essence, Eyes cream, Sunscreen cream, and So on.

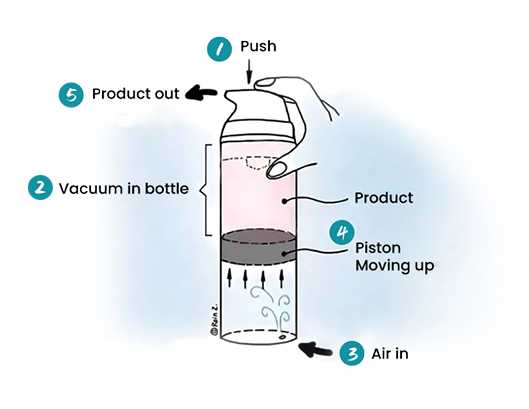

Compared with the open bottle that needs frequent contact with air, the advantages of the airless bottle are obvious: the design of air isolation effectively avoids the oxidative deterioration and bacterial growth of the product's internal material, and can effectively maintain the activity of active ingredients, so that skin care products can play a better role.

Read More

It is applied to Thin Eyes creams, Serums, Essence, Skin care lotion and So on.

Many skin care products contain ingredients like proteins and some amino acids that are easily contaminated with bacteria and must be kept clean. If they are contaminated, they can produce substances that are harmful to human health. Airless bottles can isolate the contents from the air, so they won't easily react with the air and lose some of their original effects.

Read More

It is applied to the medical aesthetic industry. Eg eyes creams, Essence and so on.

Keep this airless container in a vacuum state, which can prevent nourishment, water, and gas, so that the cosmetics remain stable and achieve better results.

Read More

If you have any questions about our products and services, please do not hesitate to contact us. Our team will reach you within 12 hours!

We offer an expansive selection of customization options that match the unique demands of the OEM market.

Quality control is always the highest priority, upholding strict standards in every step of the manufacturing process.