About water transfer printing these details should be noted

Jul 19, 2023|

Jul 19, 2023| View:406

View:4061. Water transfer printing process

Making water transfer printing paper → paper immersion → pattern transfer paste → drying → finished product

1.1 water transfer printing paper: according to the needs of the pattern of computer processing after the output plate, and then in the water transfer printing paper (after the special treatment of the paper no longer needs to do processing) on the color pattern printing, print the cover oil on the printed base paper. Another method is to use a color laser printer to print the pattern directly on the water transfer paper and then do the water transfer printing.

1.2 Paper Immersion: the printed paper is in human water, immersion after 30 seconds out of the water, so it can slide. Pay attention to the soaking time is not too long, otherwise, it will dissolve the paper surface of the glue.

1.3 pattern transfer paste: first will be transferred to paste the surface of the object for processing, and then will soak good paper transfer paste to it, and then the excess moisture removed, and dry.

1.4 Drying: metal, ceramic, and glass items were baked in the oven at 140 ° C for 20 min; plastic items were baked at 70 ° C for 60 min; candles, helmets, or reinforced glass were not baked.

1.5 Finished product: spray a layer of transparent varnish on the surface of the baked goods, and after 12 hours of drying, make the surface of the flowers and decorations permanently combined. If you do not do this process can be, but poor fastness.

2. Water transfer printing process operation

2.1. Covering the film: the water-soluble film is pre-printed with the desired pattern;

2.2. activation: the use of special solvents to make the pattern on the film activated into an ink state.

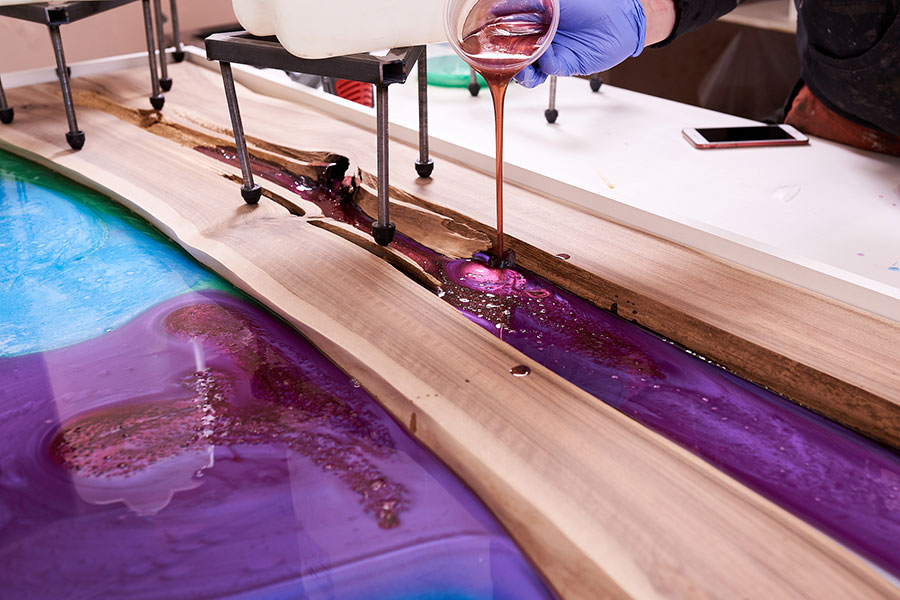

2.3 capping: the use of water pressure will be printed on the pattern on the printed matter.

2.4 Wash: will be printed on the workpiece residual impurities washed with water.

2.5 drying: will be printed parts drying.

3. There are two kinds of water transfer printing technology

One is watermark transfer technology, which mainly transmits text and Hydrographics images, while the other tends to transfer the entire surface of the product. Cubictransfer uses a water-based film that dissolves easily in water to hold images and text. Due to the excellent tension of the water-coated film, it is easy to wrap around the product surface to form a graphic layer, the product surface like spray paint gets a completely different appearance. Drape transfer technology can cover the color pattern on any shape of workpiece, to solve the problem of three-dimensional product printing for manufacturers. Surface draping can also be applied to the surface of the product in different patterns, such as leather, Wood, jade marble patterns, etc. In the printing process, because the product surface does not need to contact with the printing film, can avoid damaging the product surface and its integrity.

Water Transfer is a special chemical treatment of the film, after printing on the required color lines, flat on the surface of the water, the use of water pressure, the color line patterns evenly transfer printed on the surface of the product, at this point the coated film is automatically dissolved in water, after cleaning and drying, and then on a transparent protective coating, this product has presented a completely different visual effect.

4. Water transfer printing inspection items

Side A:

The area is $0.5 mm (white spots/black spots are not available;

0.1 mm2 particles, do not significantly affect the appearance of OK;

0.1 mm2≤0.5 mm2 the entire A-plane does not exceed 3 particles, and the spacing between the two particles is greater than 6cm.

Side B:

The area of $0.7 mm2 particles are not available;

0.2 mm2 or less ok;

0.2 mm2≤0.7 mm2 shall not exceed 3.

2. Oil

Side A:

0.1≤0.5 mm2 is not more than 2, and there are 5cm between two points

2.0. Oil Point below 1mm2 without obvious effect on appearance.

Side B:

0.2≤0.7 mm2 not more than 2;

Oil Point below 0.2 mm2 and no obvious effect on appearance.

Common appearance problems

Pattern: the pattern is complete and clear

Color Dot: the color dot that obviously affects the appearance can not have

Foreign Body: no foreign body that obviously affects the appearance

Flow Oil: obviously flow oil can not have

Scratches: no obvious scratches

Chromatic aberration: no obvious chromatic aberration (as compared with the sample)

Fracture: Paint Crack is not allowed

Appearance Standards:

(1) classification standard of grade surface

Class A: after assembly often see the outside surface, the normal visible top surface, and do not need to bend sideways visible surface.

Class B: not often seen, but under certain conditions can see the surface. Such as side, bottom, etc.

(2) test conditions

A light requirement: Arctic daylight or indoor high-efficiency fluorescent lamp with two light sources (illumination of about 1000 lumens).

B visual distance: a class surface for 300 mm, B class surface for 500 mm.

Inspection standards according to the requirements of light source distinguish product grade surface, all grade surface coating should be free from substrate exposure, peeling and other defects, and all the surfaces should be free from scratches, bubbles, wrinkles, pinholes, accumulation of powder, and other undesirable phenomena. The eyes were scanned at a speed of 3 cm/s at the standard distance from the grading plane.

Performance criteria:

(1) non-destructive test item gloss: using the gloss meter to judge, the incidence angle 60 °, ± 5% error test qualified. Color: the color must conform to the design drawing and color plate comparison with no obvious difference.

(2) destructive test.

(3) adhesion test: 100-meter Test Method: after spraying, take a color plate, on the film surface, according to the interval of 1 mm vertical and horizontal parallel carved 11, draw 100 squares on the spray surface with appropriate force (the scratches are based on the exposed substrate), then cover and press with 3M tape at a 45 ° angle, then pull at a speed of 100mm/min to check if the contents of the squares fall off, acceptance criteria for 0 ~ 1 grade, that is, the area of not more than 5% for qualified.

(4) hardness test

A sharpened HB pencil is fixed in the middle of a horizontal trolley at a 45 ° angle to the surface of the coating film and is pushed forward 15 ~ 30 mm along a straight line. The judging standard is: no scratches show six, and the dew is qualified.

(5) solvent resistance test

Wet the cotton swabs with analytical alcohol (99.8% anhydrous alcohol) and rub the surface of the coating 50 times with 1 kg of force, a slight change in gloss may be allowed.

(6) impact resistance test

Using the test equipment, 500 grams of weight from the height of 500 mm free fall, the standard is 1/4 of the punch after the front impact, the surface coating no cracking, film loss phenomenon.

View More(Total0)Comment lists