Understand PET container manufacturing process

Jul 07, 2023|

Jul 07, 2023| View:386

View:3861. Product definition

A PET bottle is based on PET plastic material,

a plastic container obtained by one-step or two-step processing.

Pet plastics have the characteristics of light weight, high transparency, impact resistance, and not easy to break

2. Manufacturing process

2.1 Know Your Bottle

The bottle embryo is an injection molded article. As a semi-finished product of subsequent biaxial stretching/blowing of the bottle, the bottle embryo's neck has been shaped during the injection stage, and its dimensions do not change during heating and stretching/blowing, the size, weight and wall thickness of the bottle germ are the factors that we need to pay close attention to when we blow the bottle.

2.2 PET bottle molding

One step

In a machine, the injection, pull, and blowing process is called the one-step method. The one-step method is in the preform after cooling after injection to do pull blow action. Its main advantages are power-saving, high productivity, no hands, and reduced pollution.

Two-step method

The two-step method separates injection and drawing and blowing, which is also called the injection-drawing and blowing process. The first step is to inject the preform with the injection molding machine. The second step is to reheat the preform at room temperature and blow it into a bottle. The advantage of the two-step method is to purchase the preform and blow it into a bottle. Can reduce investment (personnel and equipment). The preform is much smaller than the bottle and is easy to transport and store. The preform produced in the low season can be blown into bottles in the high season.

3. Material and structure

3.1 Pet material

Pet, polyethylene terephthalic acid terephthalate polyester. Terephthalate is produced by the polymerization of terephthalic acid PTA (terephthalic acid) and ethylene glycol (EG) .

3.2 Bottle mouth common sense

Bottle mouth through the 18,20,22,24,28,33 and another diameter (corresponding to the size of the bottle mouth t), screw specifications can usually be divided into 400,410,415(corresponding to the number of threads), generally, we say, 400 for the 1-turn screw, 410 is 1.5 turn screw, 415 is high 2 turn screw

3. 3 The bottle

PP and PE bottles with more solid color, PETG, PET, and PVC materials with more transparent color, or colored transparency, there is a translucent, with less solid color. The bottle body of PET material can also be sprayed. The bottom of the blow-molding bottle has a bump. It's brighter in the light. There is a sticky line at the bottom of the blowing bottle.

3.4 Supporting

The bottle blowing kit mainly has the inner plug (PP and the PE material commonly used), the outer cover (PP and ABS and acrylic commonly used, also has electroplating, and the electrified aluminum, the spray oil toner uses), the pump head outer cover (the essence and the emulsion often uses), the QIQIUAI cover, the QIQIUAI cover (Qiqiuai cover and Qiuai cover many uses for the popular circulation daily chemical line) and so on.

4. Industry applications

PET bottles are widely used in the cosmetic industry,

mainly in the washing and nursing industry,

one shampoo, shower gel bottle, toner, make-up remover oil bottle

They are all made by blowing bottles.

5. Points for attention in purchasing

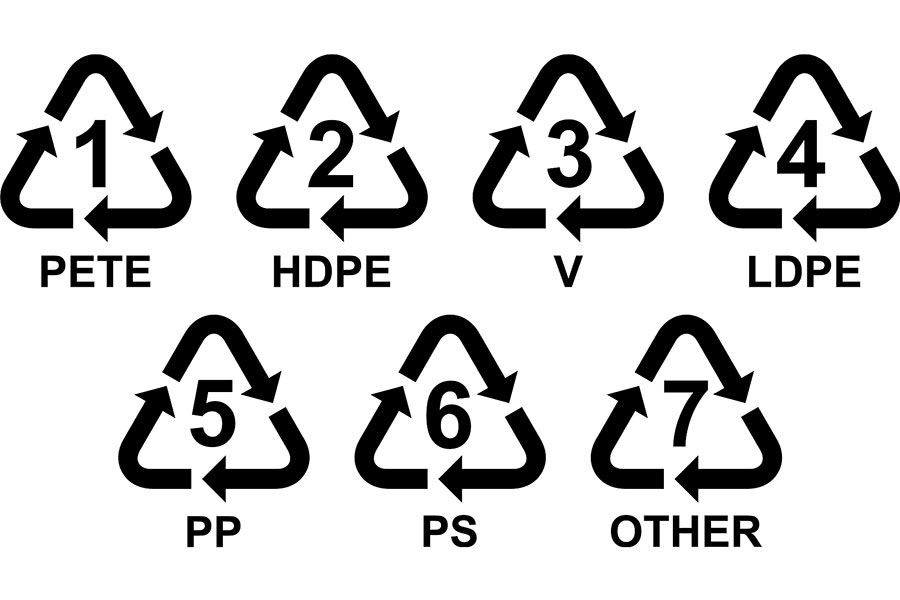

A: Blowing bottle available materials, PET is only one of them, and PE blowing bottle (more soft solid color, one-time formation) , pp blowing bottle (harder with solid color, one-time formation), PETG blowing bottle (transparency than PET, but not commonly used in China, high cost, high cost, one-time formation, non-recyclable material), PVC blowing bottle (harder, not environmentally friendly, transparency than PET, but better than PP and PE brightness)

B: one-step equipment is expensive, two-step method is relatively cheap

C: PET bottle mold is cheaper.

View More(Total0)Comment lists