A brief overview of UV glazing technology applications

Jul 05, 2023|

Jul 05, 2023| View:375

View:3751. UV varnish composition

UV varnishes are mainly composed of oligomers, active diluents, photoinitiators, and other additives. Oligomer is the most basic composition of UV varnish, its performance in the curing process and curing quality plays a decisive role. At present, the commonly used oligomers are epoxy acrylate, polyurethane acrylate, and polyester acrylate. Epoxy acrylate is one of the most widely used oligomers because of its fast curing, good adhesion, and low price.

The active diluent is used to adjust the viscosity of UV varnish, curing speed, and curing film properties. At present, most of them are acrylic monomers. According to the amount of acrylic group, it can be divided into single-functional group diluent and multi-functional group diluent. UV varnish commonly used additives have stabilizers, leveling agents, defoamers, and so on.

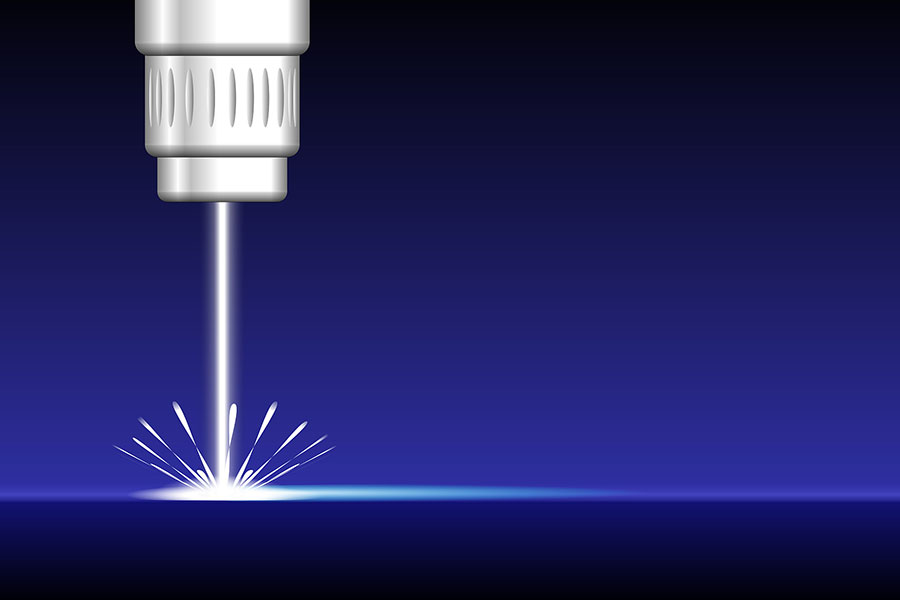

2. UV glazing process

UV glazing process is generally: Powder-corona treatment-base oil UV glazing-cooling. There are many factors affecting the process, such as ink, printing light adaptability, process conditions (coating amount, drying temperature and coating speed, etc.) selection, and the impact of external environmental conditions.

The wetting effect of the ink layer and its particle size, as well as the ink layer drying conditions, will directly affect the coating quality and rheological properties. The smoothness and absorbency of the paper on the impact of quality is particularly significant. In other factors the same case, the higher the paper smoothness, the better the glazing effect, and vice versa, easy to produce local depression. In order to obtain a high degree of smoothness of the paper, often before glazing coated with a layer of primer layer. Different paper on the absorption of varnish is different. Absorption is too strong, which will make it difficult to form a smoother film, easy to appear, and paper concave and convex state similar film. If the absorption is too weak, the penetration, solidification, and conjunctival effect in leveling will be obviously reduced, and the high-quality film can not be formed. Therefore, to choose the appropriate absorption.

3. UV glazing the main way

(1) the relationship between the glazing machine and the printing machine can be divided into offline and online glazing.

(2) according to the glazing method can be divided into roller glazing and printing on-line glazing.

(3) according to the type of glazing products can be divided into full-width UV, local UV, Matt UV, and art glazing.

4. Application of UV glazing technology

After UV glazing treatment, the paper packaging products can improve their appearance, make the printing quality thick and plump, luster rich moisture, improve the decoration effect of paper products, and can obviously improve the folding resistance and chemical resistance, improve its performance, reduce the product in the transportation, storage process loss. For high requirements of moisture-proof products (such as electrical appliances), its paper packaging through UV glazing treatment, can improve the moisture-proof ability of packaging.

UV glazing in recent years, the rapid development in the packaging and printing industry is gradually increasing the proportion, but there are also many problems to be solved. The first is security. The active diluent used in the current UV varnish has a certain volatility or irritation and still has pollution to the environment. At present, the water-based UV varnish is developed with or thickening agent instead of an active diluent, thus solving the volatile and irritant problems, which is an ideal environmental protection product.

Then there is the smell. Now it is gradually moving in the direction of low odor. At present, UV glazing packaging products have not been fully recognized by the International Food and Drug Home, and can not be in direct contact with food. Therefore, it is necessary to improve the working conditions and environment, improve the drying effect, and get a complete curing, thus reducing the smell.

Again is in the oxidation of polymerization ink adhesion. There are not only smell, low gloss, and other problems, and adhesive difficult. Now often use double glazing to improve UV glazing quality, but also to increase the cost. Therefore, need to improve the adaptability of UV varnish and ink.

Finally, there is the issue of cost reduction, although the current cost has been reduced a lot, compared to the cost of BOPP composite film composite is cheaper. But in China, UV varnishes a lot of varieties, performance is not the same. So the price is quite different. Overall, the cost is too high, the need to further reduce the cost of varnish, coating costs, and equipment operating costs.

View More(Total0)Comment lists