Do you know anything about extrusion blow molding process?

May 19, 2023|

May 19, 2023| View:317

View:317Process cost: processing cost (middle), unit cost (low)

Typical products: chemical product container packaging, consumer goods container packaging, pharmaceutical container packaging

Speed: fast, averaging 1-2 minutes per cycle

Blow molding is divided into 3 categories

Stretch blow molding (ISBM)

Extrusion blow molding (EBM)

Step 1: pour the polymer particles into the hard die, through heating and continuous extrusion of the mandrel to form a gelatinous hollow cylindrical prototype

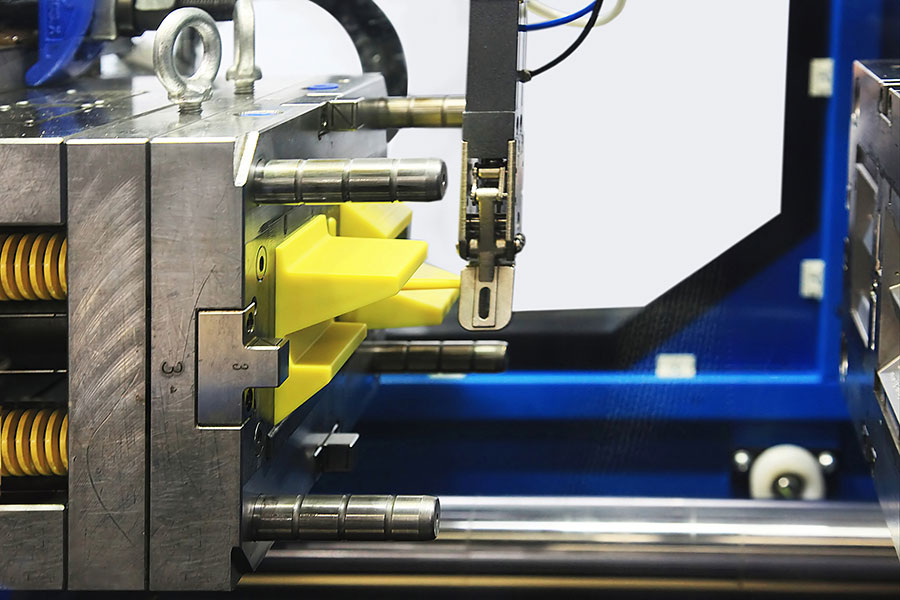

Step 2: When the hollow cylinder prototype is extruded to a certain length, the mold on the left and right sides begins to close. The top of the prototype will be cut by a blade to the suitable length of a single piece. Air will be injected into the prototype through an inflatable rod, the prototype is cooled and solidified close to the inner wall of the mold to form the desired shape

Step 3: wait for the end of cooling, the left and right sides of the mold open, part demolding

Step 4: use a repair tool to trim the edges of the part

Example: plastic detergent bottles are produced by extrusion blow molding

1. PE polymer particles are normally stored by color in an industrial funnel

2. In this example, blue PE polymer particles are continuously heated and extruded to form gelatinous hollow columnar prototypes of the same wall thickness

3. The left and right sides of the mold closed, a cylindrical prototype of the upper end was cut to fit the length

4. The inflatable rod extends into the bottleneck, and through injecting air, the rubber assembly prototype sticks to the inner wall of the mold to form the desired shape

5. The left and right sides of the die are opened and the parts are exposed (connected to the inflatable rod)

6. The inflatable bar is retracted and the repair machine trims the detergent bottle

7. Every detergent bottle needs a stress test

8. The filler fills the plastic bottle with detergent

9. The lid is automatically rotated and assembled

10. The label is automatically affixed to the bottle

View More(Total0)Comment lists