The key of getting the knowledge of packaging

Mar 12, 2018|

Mar 12, 2018| View:1397

View:1397Like a girl's face, a nice-looking appearance will attract more attention. However, perfect cosmetics packaging have to meet not only a nice-looking appearance but also material requirement, structural design needs, and regulatory and filling production needs.

1. The requirements of appearance

Cosmetics packaging is more complex, including the first layer of packaging, two or three layers of packaging, and outer transport packaging. There are many types of packaging in the first layer, including bottles (such as plastic bottles and glass bottles), soft tubes (such as plastic soft tubes, composite soft tubes, and metal soft tubes), bags (such as paper bags, plastic bags, and composite bags), Etc .; two or three layers of packaging include boxes (such as paper boxes, plastic boxes, metal boxes), labeling, skin packing and so on. Outer transport packaging, including cushion packaging and so on.

The appearance requirements of different packaging tiers have not only commonality but also particularities. The commonality includes printing patterns and writing clear, clear, not easy off, color uniformity, and so on. The appearance requirements of particularities are based on different types of packaging.

Bottle packaging

The bottle body should be smooth, uniform thickness, with no obvious scars, or deformation, and no cold bursts and cracks; the Bottle mouth should be aligned, and smooth, with no burrs and thread, bayonet With the structure should be aligned; Bottle and lid should be tight, no any sliding teeth, loose and leak; inside and outside of the bottle should be clean.

Bag packaging

No obvious wrinkles, scratches, or air bubbles, uniform color; Well-sealed, no opening, perforate, leakage; Composite bag should be tight, uniform coating, no shedding.

2. The requirements of material

In order to achieve sustainable development, bio-based biodegradable materials came into being and gradually became a hot topic in the industry. Bio-based biodegradable material is a new class of materials that are made by biological, chemical, and physical methods using renewable materials such as crops, trees, and other plants, and their residues and inclusions as raw materials.

Products made from bio-based biodegradable materials often have green, environmentally friendly, renewable raw materials, a biodegradable characteristics. At present, the United States DuPont, Germany's BASF, and other large companies are actively expanding the bio-based chemicals business. As a cosmetic developer, we hope that bio-based biodegradable materials can be used in cosmetic packaging and promote sustainable development for cosmetic packaging in the future.

3. The requirements of structural design

For cosmetics, the first layer of packaging is very important and directly related to product quality. Most of the first layer of cosmetic packaging is plastic containers, the structural design of plastic containers can not be separated from materials and molding process choices. Commonly used plastic materials from the texture can be divided into two categories of soft materials and hard materials, that is PE, PP, other typical soft materials as representative, and ABS, PMMA, other typical hard materials as representative.

The common forming process of plastic containers includes injection molding, blow molding, injection-stretch-blow molding process, etc. But no matter what kind of molding process, sealing design and capacity design is crucial.

Sealing design

Product Sealing is a compulsory quality standard in the cosmetics industry. General choose discs and quality (GW), volume, production date and shelf life or production batch number and the date of the deadline, as well as the choice of labeling GB / T191-2008 " Pictorial symbol "in the logo symbol, and the logo should be clear, complete, the right place.

Capacity design

There are two types of capacity identity: one is that the contents are not flowing at room temperature in units of weight (g, kg), and the other one is that at normal temperature the contents can flow in volume (ml, L) as a unit.

For products where the contents can flow, it is necessary to convert the required weight of the contents to volume units in grams (g) / weight (g) / product density when it is in weight (g). This is because the packaging container in the molding, is the cavity space for the most convenient and accurate detection of distilled water.

When designing the capacity of a packaging container, consider the changes in the volume and form of the cosmetic due to factors such as time and temperature, formulation and filling as well as its own viscosity, adequate space should be left in the design of the full capacity of the packaging container.

4. The requirements of regulatory

Fully understanding the relevant regulations and standards of cosmetics packaging, is the precondition and foundation. For example, the State Administration of Quality Supervision, Inspection and Quarantine issued No. 75, "Quantitative Measures for the Measurement of Quantities of packaged goods," the net content of the product clearly stipulates: that due to changes in water and other factors caused by large changes in the net content of quantitative packaging of goods, The producer shall take measures to ensure the net content of the commodity under the specified conditions is accurate.

Therefore, considering the powder products will become smaller with the extension of time, water products will lose weight over time, etc., we have to compensate for these changes. This point in the design of transparent packaging capacity is to pay special attention.

At the same time, cosmetics manufacturers also need to know the relevant national, local, and enterprise regulations and standards in time, such as "Cosmetic Label Management Regulations" and "Cosmetic Health Supervision Regulations" to ensure that the cosmetic packaging complies with relevant regulations and standards.

5. The requirements for filling production

The on-line filling is actually testing whether the packaging design is perfect and whether the quality of container production is qualified. The contents or material will be due to the mixing and the impact of materials to produce bubbles and foam, resulting in volume changes in the process of preparation and filling.

For example, the high viscosity of gels creates a significant amount of air entrapment during agitation, resulting in the storage of large quantities of bubbles in the semi-finished product that affect the volume of the product. Shampoos have an inherent blowing agent composition that can be used during filling Due to the high-speed impact and produce a large number of foam floating on the surface of the material, thereby expanding the space required for the container; cream product viscosity is high, after filling the cream body surface will produce conical protrusions phenomenon, can not be a short period of time If the product mix is completed at this time, the cream body will contact with the sealing sheet, which will not only affect the appearance of the combined product, but also cause the possibility of secondary product contamination. Therefore, these phenomena should be fully considered when designing the capacity of such products.

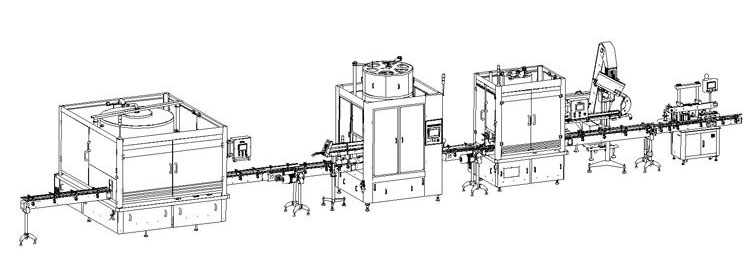

In addition, in the mass production process, the components of the package are required to be able to adapt to running on high-speed lines; the requirements of the container surface such as labels, printing patterns, and lot numbers can tolerate the friction caused by the high-speed transportation; the container structure requires high-speed transportation To maintain a stable state, can not be dumping phenomenon, otherwise, it will directly affect the normal packing process, the operator's labor intensity and the economic benefits of enterprises.

View More(Total0)Comment lists